Glass… More Than Just History

Glass has left an impression on all of our lives. It has and will for a very long time. There are and have been many different uses for glass, along with multiple ways of working with it (some more modern and some techniques that have changed very little over the years). In this reading, we hope to make the history of glass a little less transparent than glass itself.

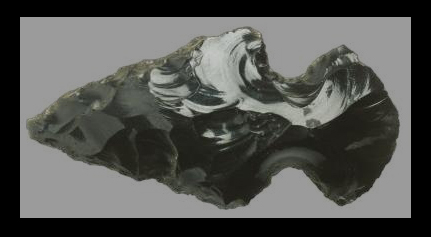

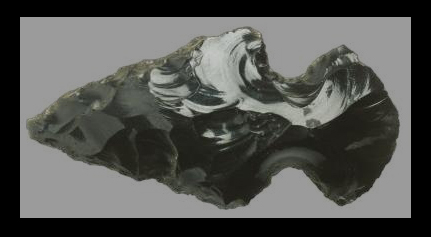

Examples of glass use dates back to as early as 2.6 million years ago. Since they did not have the means to create their own, they had to rely on natural occurrences. Sometimes the tremendous heat from a volcanic eruption would fuse rocks and sand into a glass called Obsidian (volcanic glass) which is usually dark brown or black. Lightning would strike sand and the intense heat could fuse the sand into long, slender, glass tubes called fulgurites (which are commonly called petrified lightning). Their color varies depending on the composition of the sand they formed in, ranging from black or tan to green or a translucent white. The rarest kind of naturally occurring glass on earth comes from meteorite impacts called Tektite. Natural glass made essential things in life during the

Examples of glass use dates back to as early as 2.6 million years ago. Since they did not have the means to create their own, they had to rely on natural occurrences. Sometimes the tremendous heat from a volcanic eruption would fuse rocks and sand into a glass called Obsidian (volcanic glass) which is usually dark brown or black. Lightning would strike sand and the intense heat could fuse the sand into long, slender, glass tubes called fulgurites (which are commonly called petrified lightning). Their color varies depending on the composition of the sand they formed in, ranging from black or tan to green or a translucent white. The rarest kind of naturally occurring glass on earth comes from meteorite impacts called Tektite. Natural glass made essential things in life during the  Stone Age so much easier (hunting, protection and crafting, for example). These materials were mainly use by Stone Age societies for the production of sharp cutting tools (chipping away pieces, carving it into a sharp edge) and trade. Little change in the use of this technique has been evident for several centuries.

Stone Age so much easier (hunting, protection and crafting, for example). These materials were mainly use by Stone Age societies for the production of sharp cutting tools (chipping away pieces, carving it into a sharp edge) and trade. Little change in the use of this technique has been evident for several centuries.

The earliest known hand-made glass object dates back to as early as 3100 BC. Beads were made in Egypt and Mesopotamia. Little is known about the true ideas behind this creation, accidental or intentional. It is speculated that they were likely created on accident while making non-clay based ceramic decoration called “faience.” The beads were formed by a process similar to ceramic glazing (ceramic or porcelain objects coated in a melted material that hardens, leaving a glossy layer). This fabricated glass lacked the translucency of glass made by natural causes, but was workable to give shape and color for decoration. These beads were used as a currency throughout the Syrian-Canaanite region, which was a major center of glass production and ahead of most in the development of new technologies.

The beads were formed by a process similar to ceramic glazing (ceramic or porcelain objects coated in a melted material that hardens, leaving a glossy layer). This fabricated glass lacked the translucency of glass made by natural causes, but was workable to give shape and color for decoration. These beads were used as a currency throughout the Syrian-Canaanite region, which was a major center of glass production and ahead of most in the development of new technologies.

Evidence of new techniques begins to show up throughout Egypt and Western Asia in the 1500’s BC. Rapid growth in technology was indicated by the discovery of colored glass ingots (bars created by pouring melted materials into a cast mold), containers (bowls, pitchers, cups and vases), and more beads (which started being used more often everywhere). Examples of these can be found in Ahotep’s treasure (Ancient Egyptian queen during the end of the Seventeenth Dynasty of Ancient Egypt), and in Megiddo (a site on an ancient trade route which connected Egypt and Assyria). Containers from this era were produced by winding molten glass around a sand and clay mold, supported by a metal rod. The glass would adhere to the mold. It was then fused with repeated heating. A metal raking tool was used to make patterned ribbons sprout out of the fused glass. At this point the glass would get held against a flat slab and turned, in order to press the decorative ribbon shapes into the body. Handles and the base which the vessel would stand on were then applied separately. After the glass slowly cools, the sand and clay get scraped out. Many of the decorative engravings at the time were produced using the grinding / carving technique used in stone working. This was done when the glass was cold. The techniques for fusing glass from raw materials were not distributed as common knowledge. It was a treasured technological commodity. Glass workers without this secret relied heavily on imports, often in the form of glass bars.

Glass and makers of glass continued to increase in value. In the 14th century BC, Egypt was known to take glass-makers prisoner from successful military campaigns. Production of glass came to a halt in the Late Bronze Age as disasters overtook civilizations. Evidence of glass making picked up again in Syria and Cyprus in 900 BC. Techniques used to make colorless glass were discovered. Over the next 500 years, glass production mostly came out of Alessandria.

The earliest documented instructions for glass-making dates back to around 650 BC. In the form of tablets, located in the library of the Assyrian king Ashurbanipal, a manual on how to make glass was discovered. Ashurbanipal established the first systematically organized library in the ancient Middle East.

Between 150 and 350 BC new techniques were discovered to make larger pieces, notably table wares. Slumping is the process of setting heated, softened glass (not fully molten) over a mold forming a dish. Millefiori was also introduced (canes of multi-colored glass were sliced; the slices were arranged together and fused in a mold to create a mosaic-like effect). During this period, colorless glass became a prized item and methods for achieving this product were better understood.

During the 1st century BC, glass blowing was discovered on the Syro-Palestinian coast. This method revolutionized the industry. The method used metal tubes to inflate molten glass into a bubble. The bubble is then rotated or rolled onto a flat surface to get the desired shape. The conquest of Judea by the Romans in 63 BC caused the spread in use of glass products throughout the Roman Empire. The discovery of clear glass in Alexandria, 100 AD, was used by Romans for architectural purposes. Windows were installed in the most luxurious buildings. Over the next thousand years, methods and uses of glass spread through southern Europe and beyond.

1226 AD, Sussex produced the first “Broad Sheet.” It is a hand-blown glass, made by blowing molten glass into an elongated balloon shape. While the glass is still hot, the ends are cut off and the resulting cylinder is split with shears and flattened on an iron plate. 1330 AD, Rouen first produced the method known as “Crown Glass”. This technique uses a hand blown globe that gets attached to a metal rod, flattened by reheating and spinning the rod until the glass shapes into a disk. These were used for windows. 1620 AD, London produced mirrors using Broad Sheets. They would hand grind and polish the front and back of the Broad Sheet. This process was known as “Blown Plate.” In 1688 AD, France made an improvement to the Blown Plate process by casting the molten glass into a mold, instead of blowing it by hand. 1843 AD, Henry Bessemer invented an early form of “Float Glass.” This is defined by pouring molten glass onto molten metal. The result between the different densities of the two substances created a flat surface and uniform thickness. At the time, this was not an industrial success because it was too expensive. Modern windows are made from this method. Between then and now, several upgrades to these techniques have been made, as well as mechanical implementation. Even today, most glass is worked with some variation of these techniques because there has been little need to change them over the centuries.

Examples of glass use dates back to as early as 2.6 million years ago. Since they did not have the means to create their own, they had to rely on natural occurrences. Sometimes the tremendous heat from a volcanic eruption would fuse rocks and sand into a glass called Obsidian (volcanic glass) which is usually dark brown or black. Lightning would strike sand and the intense heat could fuse the sand into long, slender, glass tubes called fulgurites (which are commonly called petrified lightning). Their color varies depending on the composition of the sand they formed in, ranging from black or tan to green or a translucent white. The rarest kind of naturally occurring glass on earth comes from meteorite impacts called Tektite. Natural glass made essential things in life during the

Examples of glass use dates back to as early as 2.6 million years ago. Since they did not have the means to create their own, they had to rely on natural occurrences. Sometimes the tremendous heat from a volcanic eruption would fuse rocks and sand into a glass called Obsidian (volcanic glass) which is usually dark brown or black. Lightning would strike sand and the intense heat could fuse the sand into long, slender, glass tubes called fulgurites (which are commonly called petrified lightning). Their color varies depending on the composition of the sand they formed in, ranging from black or tan to green or a translucent white. The rarest kind of naturally occurring glass on earth comes from meteorite impacts called Tektite. Natural glass made essential things in life during the  Stone Age so much easier (hunting, protection and crafting, for example). These materials were mainly use by Stone Age societies for the production of sharp cutting tools (chipping away pieces, carving it into a sharp edge) and trade. Little change in the use of this technique has been evident for several centuries.

Stone Age so much easier (hunting, protection and crafting, for example). These materials were mainly use by Stone Age societies for the production of sharp cutting tools (chipping away pieces, carving it into a sharp edge) and trade. Little change in the use of this technique has been evident for several centuries.The earliest known hand-made glass object dates back to as early as 3100 BC. Beads were made in Egypt and Mesopotamia. Little is known about the true ideas behind this creation, accidental or intentional. It is speculated that they were likely created on accident while making non-clay based ceramic decoration called “faience.”

The beads were formed by a process similar to ceramic glazing (ceramic or porcelain objects coated in a melted material that hardens, leaving a glossy layer). This fabricated glass lacked the translucency of glass made by natural causes, but was workable to give shape and color for decoration. These beads were used as a currency throughout the Syrian-Canaanite region, which was a major center of glass production and ahead of most in the development of new technologies.

The beads were formed by a process similar to ceramic glazing (ceramic or porcelain objects coated in a melted material that hardens, leaving a glossy layer). This fabricated glass lacked the translucency of glass made by natural causes, but was workable to give shape and color for decoration. These beads were used as a currency throughout the Syrian-Canaanite region, which was a major center of glass production and ahead of most in the development of new technologies.Evidence of new techniques begins to show up throughout Egypt and Western Asia in the 1500’s BC. Rapid growth in technology was indicated by the discovery of colored glass ingots (bars created by pouring melted materials into a cast mold), containers (bowls, pitchers, cups and vases), and more beads (which started being used more often everywhere). Examples of these can be found in Ahotep’s treasure (Ancient Egyptian queen during the end of the Seventeenth Dynasty of Ancient Egypt), and in Megiddo (a site on an ancient trade route which connected Egypt and Assyria). Containers from this era were produced by winding molten glass around a sand and clay mold, supported by a metal rod. The glass would adhere to the mold. It was then fused with repeated heating. A metal raking tool was used to make patterned ribbons sprout out of the fused glass. At this point the glass would get held against a flat slab and turned, in order to press the decorative ribbon shapes into the body. Handles and the base which the vessel would stand on were then applied separately. After the glass slowly cools, the sand and clay get scraped out. Many of the decorative engravings at the time were produced using the grinding / carving technique used in stone working. This was done when the glass was cold. The techniques for fusing glass from raw materials were not distributed as common knowledge. It was a treasured technological commodity. Glass workers without this secret relied heavily on imports, often in the form of glass bars.

Glass and makers of glass continued to increase in value. In the 14th century BC, Egypt was known to take glass-makers prisoner from successful military campaigns. Production of glass came to a halt in the Late Bronze Age as disasters overtook civilizations. Evidence of glass making picked up again in Syria and Cyprus in 900 BC. Techniques used to make colorless glass were discovered. Over the next 500 years, glass production mostly came out of Alessandria.

The earliest documented instructions for glass-making dates back to around 650 BC. In the form of tablets, located in the library of the Assyrian king Ashurbanipal, a manual on how to make glass was discovered. Ashurbanipal established the first systematically organized library in the ancient Middle East.

Between 150 and 350 BC new techniques were discovered to make larger pieces, notably table wares. Slumping is the process of setting heated, softened glass (not fully molten) over a mold forming a dish. Millefiori was also introduced (canes of multi-colored glass were sliced; the slices were arranged together and fused in a mold to create a mosaic-like effect). During this period, colorless glass became a prized item and methods for achieving this product were better understood.

During the 1st century BC, glass blowing was discovered on the Syro-Palestinian coast. This method revolutionized the industry. The method used metal tubes to inflate molten glass into a bubble. The bubble is then rotated or rolled onto a flat surface to get the desired shape. The conquest of Judea by the Romans in 63 BC caused the spread in use of glass products throughout the Roman Empire. The discovery of clear glass in Alexandria, 100 AD, was used by Romans for architectural purposes. Windows were installed in the most luxurious buildings. Over the next thousand years, methods and uses of glass spread through southern Europe and beyond.

1226 AD, Sussex produced the first “Broad Sheet.” It is a hand-blown glass, made by blowing molten glass into an elongated balloon shape. While the glass is still hot, the ends are cut off and the resulting cylinder is split with shears and flattened on an iron plate. 1330 AD, Rouen first produced the method known as “Crown Glass”. This technique uses a hand blown globe that gets attached to a metal rod, flattened by reheating and spinning the rod until the glass shapes into a disk. These were used for windows. 1620 AD, London produced mirrors using Broad Sheets. They would hand grind and polish the front and back of the Broad Sheet. This process was known as “Blown Plate.” In 1688 AD, France made an improvement to the Blown Plate process by casting the molten glass into a mold, instead of blowing it by hand. 1843 AD, Henry Bessemer invented an early form of “Float Glass.” This is defined by pouring molten glass onto molten metal. The result between the different densities of the two substances created a flat surface and uniform thickness. At the time, this was not an industrial success because it was too expensive. Modern windows are made from this method. Between then and now, several upgrades to these techniques have been made, as well as mechanical implementation. Even today, most glass is worked with some variation of these techniques because there has been little need to change them over the centuries.